The back office, built for founders

We’ve worked with over 800 startups—from first-time founders at pre-seed to fast-moving teams raising Series A and beyond—and we’d love to help you navigate whatever’s next.

Here’s how we’re willing to help you:

Incorporating a new startup? We’ll take care of it—no legal fees, no delays.

Spending at scale? You’ll earn 3% cash back on every dollar spent with our cards.

Transferring $250K+? We’ll add $2,000 directly to your account.

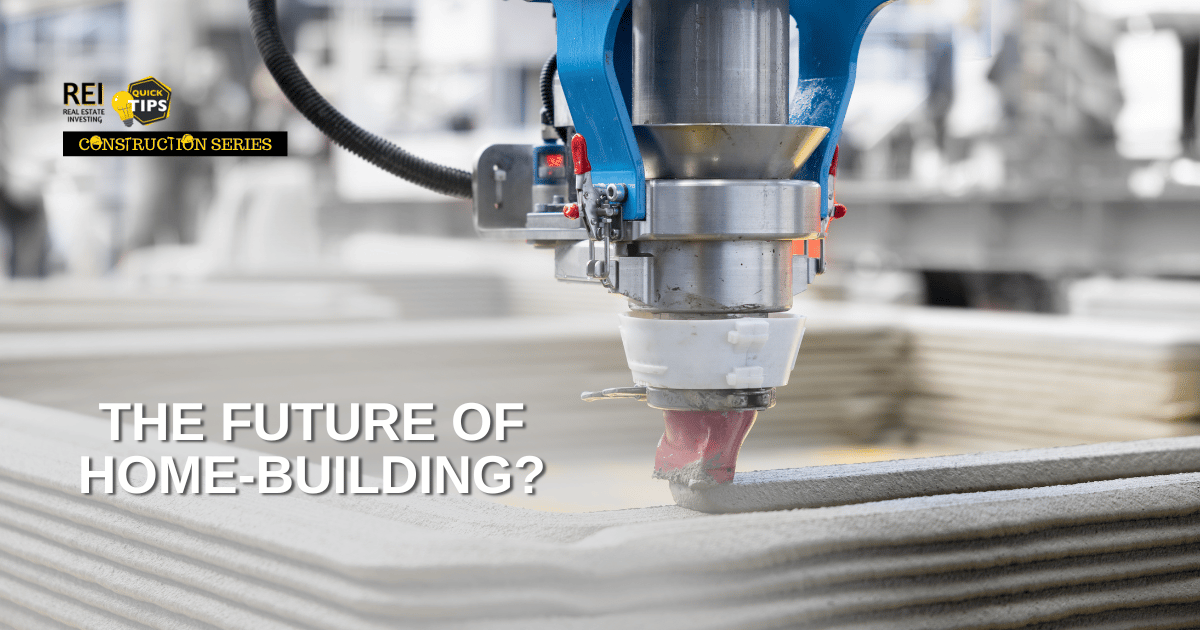

Concrete, Curves, and a “Printer” the Size of A Truck

The idea of “printing” a house might sound like sci-fi… until you realize it’s been happening for more than a decade. Large-format 3D printers using concrete or composite materials are already building homes in the U.S. and around the world. But is it a fad, a niche, or the future of housing? Let’s break it down.

A Brief History of 3D-Printed Homes

The first experimental 3D-printed structures appeared in the early 2010s, mostly as proof-of-concept projects. By the mid-2010s, companies like ICON in the U.S. and Winsun in China were producing full-sized homes. Early builds were small and basic, aimed at affordable housing and disaster relief.

Today, several companies offer 3D-printed homes commercially, often in planned developments where speed, cost, and uniformity are advantages.

Current Status and Availability

U.S. Projects: Small developments in Texas, California, and Virginia are printing homes for sale now.

International: Countries in Europe, the Middle East, and Latin America are experimenting with printed housing for low-cost and mid-market buyers.

Access: Availability is still limited to specific regions where printers and crews are based — you can’t just call your local builder and order one (yet).

Design Considerations

Form: The printing process lends itself to curved walls and organic shapes as easily as straight lines, giving more architectural freedom.

Finish: Printed walls have a layered “contour” texture unless smoothed over — some buyers love the look, others don’t.

Customization: Designs can be adapted for specific needs, but the printer’s dimensions and the material’s properties set hard limits.

Suitability for Harsh Climates

Hurricane Zones: Properly engineered concrete-printed walls can handle high wind loads and impact resistance, but roof design and anchoring still matter.

Tornado Alley: The same strength applies, but as with any home, debris impact resistance and foundation anchoring are key.

Flood Zones: Concrete resists water damage better than wood, but you still have to plan for elevation and drainage.

Durability

Printed concrete walls can outlast traditional stick framing and are resistant to rot, termites, and mold.

Lifespan is measured in decades — potentially a century or more if maintained.

Insulation

Most systems print structural walls and then add insulation layers either inside or within a cavity wall system.

Thermal performance can match or exceed code requirements, but climate-specific design still matters.

Appearance

Expect that layered, ribbed surface unless you apply a skim coat or other finish. Some buyers see it as modern and distinctive; others see “unfinished.”

Future Remodeling Issues

Cutting into printed concrete to add doors, windows, or utilities later is much harder than in wood framing.

Changes require specialized tools and expertise — not a DIY job.

Wiring and Plumbing

Typically installed during or immediately after printing, using conduits and chases designed into the walls.

Late changes are costly, so planning is critical.

Cost Compared to Other Construction

Today: Comparable to — or slightly less than — traditional construction in some regions, especially for simple designs.

Savings: Labor costs drop because fewer workers are needed, and builds can finish in days instead of weeks.

Materials: Concrete prices fluctuate, so savings aren’t guaranteed.

Bottom Line

3D-printed homes aren’t for everyone — yet. But they’re proving themselves as durable, customizable, and efficient alternatives to stick-built housing. If you’re in a region where they’re available, it’s worth exploring. In the right market and with the right design, printing your next project might be the smartest play you make.

Voice AI Security That Impacts Your Bottom Line

Learn how enterprise IT and ops leaders are using compliance to unlock Voice AI scale—deploying faster, reducing risk, and accelerating procurement.

This guide shows why HIPAA, GDPR, and SOC 2 are now deal-makers, not blockers. From securing PHI to routing across 100+ sites, see how security-first platforms reduce friction and enable real-world rollout across healthcare, insurance, and more.